Sewage sludge processing systems in Scotland

This report on sewage sludge processing systems is part of the research project undertaken by the James Hutton Institute on the impacts on human health and environment arising from the spreading of sewage sludge to land (CR/2016/23).

1 Sludge processing in Scotland

During wastewater treatment, sludges can be generated by several processes. Incoming wastewater is first screened to remove gross physical contaminants, and then settled. The settling process gives rise to primary sludge and a clarified supernatant, which is then passed forward for secondary treatment. Secondary treatment is normally aerobic, with aerobic microorganisms consuming the nutrients in the supernatant. When these microorganisms are settled out of suspension, they constitute biological or ‘activated’ sludge. Both primary and biological sludges are then subjected to further treatment, which converts them to biosolids suitable for use in markets that include: agriculture, land restoration and thermal energy recovery.

Sludges can be processed on the wastewater treatment works where they arise (‘indigenous’ sludges) or be transported to another sludge treatment centre for processing (where they become ‘imported’ sludges). The extent of transfer of sludges between sites will depend on inherent treatment capacities, as well as planned or unscheduled maintenance. Thus, some wastewater treatment works will always plan to send their sludges to a particular sludge treatment centre, whilst others will send to a convenient treatment centre that has capacity at that time. This web of logistical connections makes it difficult to track biosolids back through the treatment process to their original point of origin in any given wastewater catchment. Some examples of these connections are given in Table 1-3. A map of waste water treatment facilities in Scotland (treating loads greater than a population equivalent (pe) of 2,000) is provided in Figure 1-1.

Our focus in this section is on the sludge treatment centres themselves – the processes they employ to treat sludges (whether indigenous or imported), and the quantities of biosolids that are then despatched for agricultural use. Different sludge treatment processes provide different opportunities for hazard management – but by taking the process from the point at which sludges are treated (rather than the point at which wastewaters are treated) means that some hazard management options are omitted. For example, Scottish sludges are not usually composted or subjected to other active aerobic treatments – hazards present in wastewater that require aerobic processing to degrade must therefore be addressed during wastewater (rather than sludge) treatment.

Sludge treatment in Scotland is split between sites that are owned and operated by Scottish Water (the Scottish Water ‘core’ sites) and sites that are owned and operated by third parties (the Scottish Water ‘PPP’ or Public-Private-Partnership sites). There are 32 core sites (Figure 1-2 and Table 1-1) and 21 PPP sites (Figure 1-3). Not all sludge treatment centres produce sludges ready for their final market destinations – for example, only 14 of the PPP centres despatched sludges to market in 2017 (Table 1-2), whilst the remainder despatched sludge to other sites for further processing ( Table 1-3). The majority of sludges destined for use in agriculture are produced by the PPP sites (Figure 1-5).

| Sludge treatment centre | Sludge destination | Output (tds) |

|---|---|---|

| Allanfearn | Agriculture | 1,671 |

| Aviemore | PPP site | 127 |

| Balivanich | Land restoration | 52 |

| Brechin | PPP site | 596 |

| Broadford | PPP site | 87 |

| Cumnock | Agriculture | 491 |

| Cupar | Land restoration | 368 |

| Dalderse | Agriculture and Land restoration | 790 |

| Dalmuir | Land restoration | 3,033 |

| Dornoch | PPP site | 262 |

| Dunfermline | Agriculture and Land restoration | 3,216 |

| Galashiels | Agriculture | 1,155 |

| Girvan | Agriculture | 565 |

| Hawick | Agriculture | 149 |

| Huntly | PPP site | 147 |

| Invergordon | Agriculture | 730 |

| Kinneil Kerse | Agriculture | 3,163 |

| Kirkcaldy | Land restoration | 770 |

| Lochgilphead | Land restoration | 87 |

| Nairn | PPP site | 189 |

| Oban | Land restoration | 299 |

| Orkney | Agriculture | 295 |

| Perth | Agriculture | 4,651 |

| Shetland | Landfill | 363 |

| Shieldhall | Land restoration | 1,361 |

| St Andrews | Land restoration | 447 |

| Stirling | Agriculture and Land restoration | 449 |

| Stornoway | Agriculture | 115 |

| Thurso | Agriculture | 561 |

| Troqueer | Land restoration | 1,752 |

| Ullapool | PPP site | 24 |

| Wick | PPP site | 141 |

| Sludge treatment centre | Sludge destination | Output (tds) |

|---|---|---|

| Inverness | Agriculture | 2,661 |

| Hatton | Agriculture | 5,481 |

| Nigg | Agriculture | 13,140 |

| Persley | Land restoration | 159 |

| Peterhead | Land restoration | 267 |

| Fraserburgh | Land restoration | 58 |

| Lossiemouth | Agriculture | 3,102 |

| Seafield | Agriculture and Land restoration | 20,318 |

| Newbridge | Land restoration | 2,306 |

| East Calder | Exported to other sites | |

| Levenmouth | Agriculture and Incineration | 3,373 |

| Meadowhead | Agriculture, Land Restoration and Incineration | 8,985 |

| Dalmuir | Land restoration | 2,724 |

| Daldowie | Agriculture, Land Restoration and Incineration | 47,332 |

| PPP site | Sources of sludge |

|---|---|

| Inverness | Indigenous sludge, imports from Fort William, plus Scottish Water imports |

| Hatton | Indigenous sludge plus Scottish Water imports |

| Nigg | Indigenous sludge, imports from Persley, Peterhead, Fraserburgh, plus Scottish Water imports |

| Lossiemouth | Indigenous sludge, imports from Buckie, Banff/Macduff, plus Scottish Water imports |

| Seafield | Indigenous sludge, occasional imports from Newbridge, East Calder, Blackburn, Whitburn, plus Scottish Water imports |

| Newbridge | Indigenous sludge, imports from East Calder, Blackburn, Whitburn, plus Scottish Water imports |

| Levenmouth | Indigenous sludge, plus Scottish Water imports |

| Daldowie | Sludge from Dalmuir and Scottish Water WWTW (Daldowie, Shieldhall, Paisley, Dalmarnock and Erskine) by pipeline, and from Scottish Water tankered imports |

| Meadowhead | Indigenous sludge, plus imports from Stevenston and Inverclyde |

1.1 Types of treated sludge applied to agricultural land in Scotland

Broadly, six different sludge treatment process are undertaken across the fleet of Scottish Water core and PPP sites:

1. Advanced Anaerobic Digestion, followed by de-watering to produce biosolids cake with dry matter of around 30%;

2. Drying (without prior anaerobic digestion or other stabilisation), to produce biosolids pellets with a dry matter of around 95%;

3. Liming, in which sludges are mixed with lime or quicklime before or after de-watering, to produce biosolids cake with dry matter of around 40%;

4. Conventional Anaerobic Digestion, followed by de-watering to produce biosolids cake with dry matter of around 25%;

5. Conventional Anaerobic Digestion, followed by de-watering and then drying and pelletisation to produce biosolids pellets with a dry matter of around 95%;

6. Conventional Anaerobic Digestion, with the whole (liquid) sludge applied to land at a dry matter of around 4%.

The relative quantities of different types of treated sludge applied to agricultural land are presented in Figure 1-6. The most significant tonnage is in the form of cake produced by Advanced Anaerobic Digestion, followed by thermally dried sludge pellets and then lime pasteurised cake. From discussions with industry experts, we understand that no liquid sludges are now applied to land in Scotland.

Within some of these categories (for example, liming), there are site-specific differences relating to the points and form at which lime is introduced to the process – however, the aim of lime treatment (as with all other sludge treatments) is to manage pathogen loading in the sludge. Specifically, the aim is to produce biosolids that can either be considered Conventionally or Enhanced-treated, in line with the requirements of the Safe Sludge Matrix (Section 2.2.1):

1. Conventionally Treated = 2log10 (or 100-fold) kill of E. coli;

2. Enhanced Treated = 6log10 (or 1,000,000-fold) kill of E. coli and no Salmonella present

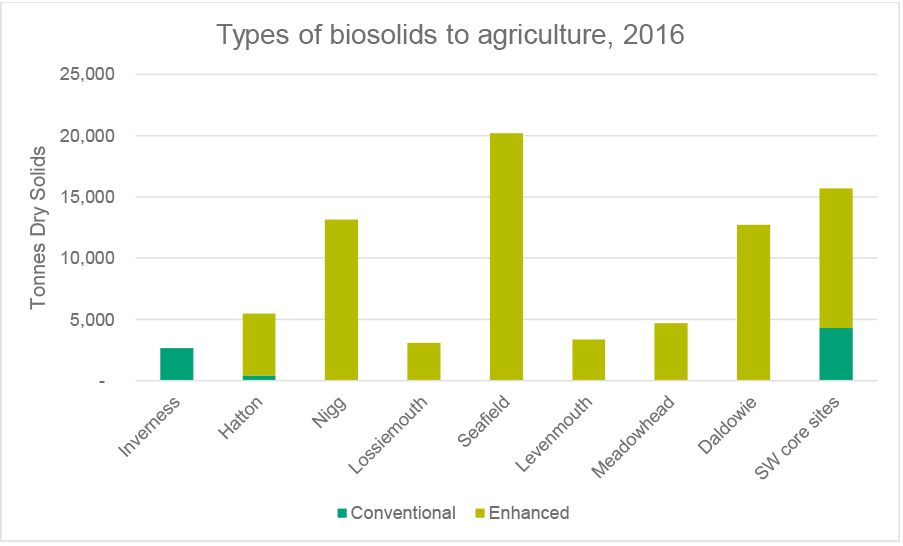

The terminology used in reporting sludge treatment data in Scotland lists markets that include ‘Farmland Conventional’ and ‘Farmland Advanced’ ((for example, see https://www.watercommission.co.uk/view_2016-17.aspx) (Figure 1-13)). We have assumed that ‘Farmland Advanced’ means biosolids that comply with the Safe Sludge Matrix category ‘Enhanced Treated’, and have set out our wider interpretation of sludge treatment efficacy in Table 1-4.

| Sludge treatment process | Conventional or Advanced? | Safe Sludge Matrix equivalent |

|---|---|---|

| Advanced AD and de-watering | Advanced | Enhanced Treated |

| Drying only | Advanced | Enhanced Treated |

| Liming | Advanced | Enhanced Treated |

| AD and de-watering | Conventional | Conventionally Treated |

| AD and drying | Advanced | Enhanced Treated |

| AD | Conventional | Conventionally Treated |

1.2 Sludge treatment approaches

As set out above, six different types of treatment system are applied to sludges destined for application to agricultural land in Scotland. Each of these systems comprise combinations of different tertiary (sludge) processing techniques, each of which has the potential to impact differently on different hazards present in the sludge. The key objective of tertiary treatment is compliance with the Safe Sludge Matrix – delivering consistent impact on indicator pathogens – but changes in pH and temperature may also impact on other hazards of interest. This potential is considered in Section 0, whilst the different processing techniques as listed in Table 1-4 are illustrated in Figure 1-7 to Figure 1-11, below.

1.2.1 Primary and Secondary Treatments

Primary treatment usually comprises clarification of the raw effluent, whereby the incoming wastewater is held in a quiescent basin – allowing heavy solids to settle to the bottom while oil, grease and lighter solids float to the surface. This principal stage is the mainstay of sludge production in wastewater treatment plants. The supernatant liquor is passed forwards for secondary treatment, whilst the settled sludge (‘primary sludge’) is collected and passed forwards for further treatment.

Secondary treatments are employed to reduce biological and suspended matter in the liquor. This is achieved using the indigenous waterborne microorganisms to biologically degrade the organic material in a well aerated liquor. Such treatments produce a final effluent (normally suitable for discharge to water body, following any final polishing) and a biological sludge (‘Activated Sludge’). Surplus Activated Sludge is collected and passed forwards for tertiary treatment, along with primary sludges.

1.2.2 Tertiary treatments

Anaerobic Digestion processes are commonly applied to sewage sludges, since they serve to break down organic matter whilst simultaneously generating renewable energy in the form of biogas (~60% CH4 and 40% CO2). AD processes are usually mesophilic, operating at temperatures of around 35°C – and heat is normally required to maintain digester contents at optimum temperatures. Mesophilic Anaerobic Digestion (MAD) can deliver a 2log10 reduction in E. coli (Mara & Horan, 2003) or Conventionally Treated biosolids.

Advanced Anaerobic Digestion systems incorporate pre-treatment techniques ahead of MAD. In Scotland, the most common pre-treatment is Thermal Hydrolysis or THP. THP was originally designed as a method to improve the dewaterability and degradability of sludge. However, when used as a pre-treatment to anaerobic digestion, the rate of biogas production and the efficiency of the digestion process are also improved. Sludge is generally heated to a temperature between 130 – 200°C for about 30 minutes in a pressure vessel. The sudden release of pressure results in cell lysis, releasing intracellular contents and reducing sludge viscosity. This improves the bioavailability of the sludge, enhancing the performance of anaerobic digestion by allowing biogas to be produced more rapidly than without THP. This can, in turn, allow digestion vessels to be smaller and/or retention times to be decreased.

Since 1995, the Cambi process has been the major THP technology used in AAD. Sludges are first dewatered to 17% dry solids before being steam heated under pressure to between 150 and 180°C. These conditions are held for up to 30 minutes before the treated sludge is flashed (rapidly de-pressurised) into a flash tank. Veolia also supply THP systems, with different configurations that can treat sludges either in batches, or continuously (Hii et al., 2017). AAD systems incorporating THP can reduce E. coli populations to undetectable levels (Martinez & Lema, 2017) and as such are capable of delivering the 6log10 reductions required for Enhanced Treated biosolids.

Thermal Drying can be applied to raw sludges or those that have undergone preliminary treatment (such as MAD or AAD). The attraction of thermal drying is that it reduces sludge volumes very significantly (thereby reducing the costs of downstream haulage and land application). However, this energy intensive process normally requires heat recovery from other plant processes for it to be economically viable, and benefits from efficient initial dewatering of sludges. The temperatures achieved during drying (~450°C) are sufficient to meet the pathogen reduction requirements of Enhanced Treated biosolids (Mara & Horan, 2003). The energy requirements for thermal drying mean that this technique is normally applied to sludges intended for subsequent incineration with energy recovery[1]. However, as is evident from Figure 1-6, dried sludges comprise a significant proportion of biosolids applied to agricultural land in Scotland.

Liming can raise the temperature of sludges to over 55°C, and pH to more than 12. When held at such elevated pH for more than two hours, this technique is capable of delivering Enhanced Treated biosolids (Mara & Horan, 2003). Lime can be added to sludges in various chemical and physical forms, with the efficacy of mixing having a direct relationship to odour potential from the treated sludge (Mangus et al, 2006).

1.2.3 Types of biosolids supplied for agricultural use in Scotland

The proportion of biosolids applied to agricultural land in Scotland has remained relatively consistent over the past decade (Figure 1-12), ranging from 52,381 tonnes (dry solids) in 2007 to 45,646 tonnes (dry solids) in 2017. Of this tonnage, the significant majority is categorised as Enhanced Treated (Table 1-5 and Figure 1-13), with small contributions of Conventionally Treated sludges from both PPP and Scottish Water core sites. Enhanced status provides biosolids with the greatest degree of flexibility in terms of access to potential agricultural markets.

| Market / biosolids end point | Quantity (tonnes dry solids) | Proportion (%) |

|---|---|---|

| Agriculture (Conventionally Treated) | 3,279 | 3.2 |

| Agriculture (Enhanced Treated) | 42,367 | 41 |

| Landfill | 393 | 0.4 |

| Incinerated | 37,275 | 36 |

| Land reclamation | 19,617 | 19 |

| Other | 242 | 0.2 |

| Total | 103,173 | 100 |

1.2.4 Options for hazard management during processing

As noted above, biosolids supplied for agricultural use arise from one of five different treatment processes (six if liquid sludges are considered). The relative quantities of sludge from these different processes are listed in Table 1-6.

| Plant | Treatment type | Tonnage to agriculture |

|---|---|---|

| Nigg | THP-AD and dewatering | 13,140 |

| Seafield | THP-AD and dewatering | 20,189 |

| Daldowie | No digestion, cake dried to pellets | 12,717 |

| Levenmouth | No digestion, cake dried to pellets | 3,350 |

| Lossiemouth | No digestion, cake dried to pellets | 3,102 |

| Meadowhead | No digestion, cake dried to pellets | 4,687 |

| Dunfermline* | Lime Pasteurised Cake | 3,216 |

| Girvan | Lime Pasteurised Cake | 565 |

| Invergordon | Lime Pasteurised Cake | 730 |

| Kinneil Kerse | Lime Pasteurised Cake | 3,163 |

| Orkney | Lime Pasteurised Cake | 295 |

| Perth | Lime Pasteurised Cake | 4,651 |

| Stornoway | Lime Pasteurised Cake | 115 |

| Thurso | Lime Pasteurised Cake | 561 |

| Allanfearn | AD and dewatering | 1,671 |

| Cumnock | AD and dewatering | 491 |

| Dalderse* | AD and dewatering | 790 |

| Galashiels | AD and dewatering | 1,155 |

| Inverness | AD and dewatering | 2,661 |

| Stirling* | AD and dewatering | 449 |

| Hatton | AD, cake dried to pellets | 5,481 |

| Hawick+ | AD (no dewatering) | 149 |

*Note that for these sites, data do not discriminate between tonnages to agriculture and land restoration. For the purposes of reporting, we have assumed that the whole tonnage from each site is supplied to agriculture

+The output from Hawick is liquid sludge. It is our understanding that no liquid sludge is now applied to agricultural land in Scotland (pers comm Debbie Neely, Entrust Environmental)

Whilst sludge quality is normally focussed on pathogen management (and classification according to Enhanced or Conventionally Treated), the different treatment processes may afford different opportunities for managing other hazards known to be present in sludges. These processes can be simplified to:

1. Elevated pressure and temperature (thermal hydrolysis);

2. Elevated temperature (drying);

3. Elevated pH (liming); and

4. Anaerobic Digestion.

Of these processes, it is possibly anaerobic digestion that has received most attention as a ‘hazard attenuation’ step in sludge treatment, with various authors having previously considered the impact of AD on hazards that include (for example) pharmaceutical and personal care products (PPCPs). Carballa et al (2007) report varying degrees of reduction through anaerobic digestion on concentrations of compounds that included galaxolide, tonalide, diazepam, ibuprofen, diclofenac and estrone. They highlighted a requirement for initial adaptation or acclimatisation of digester biology to address these compounds. Samaras et al (2003) determined concentrations of a range of PPCP compounds in sludges before and after anaerobic digestion, demonstrating removal rates of more than 80% for ibuprofen and naproxen, but lower rates for endocrine disrupting compounds such as nonylphenol monoethoxylate. Narumiya et al (2013) examined the fate and removal of 48 PPCPs during anaerobic digestion of sewage sludge at full-scale sewage treatment plants, showing that sulfamethoxazole and trimethoprim were almost completely degraded (>90%); triclosan, triclocarban, and ofloxacin were moderately degraded (around 30–50%); while carbamazepine was not eliminated.

Other sludge treatment processes have received less attention, although Malmborg & Magnér (2015) examined the fate of pharmaceutical residues in sludge treatment during AD in conjunction with either pasteurization, thermal hydrolysis, advanced oxidation, or ammonia treatment. Overall, they found that AD was capable of delivering 30% reductions in concentration of a number of spiked PPCP compounds – but that it was only through the additional use of thermal hydrolysis that estrogenic compounds were removed (estrone, 17β-estradiol and 17α-ethinylestradiol).

The impacts of these processes on hazards of particular interest are considered in Section 0.

Note that (as described above) data on sludge processing omit upstream processes by which the sludges were derived, which typically include the following approaches, each of which may be capable of attenuating certain hazards in the incoming raw sewage:

- Screening

- Aerobic treatment (as applied to primary effluent, generating activated sludge that is then processed; primary sludges are not subjected to this treatment – meaning that hazards amendable to aerobic degradation may not so degrade if partitioned to sludge during initial settlement / clarification)

Contact

Email: gary.gray@gov.scot

There is a problem

Thanks for your feedback