Waste heat recovery: introductory guide

Information about waste heat recovery and its potential as a low carbon heat source, as well as the process of capturing and utilising heat from industrial and commercial processes. The recovered heat can be used in a range of applications including heat networks.

4. Commercial considerations

This section provides an introduction to some of the key non-technical issues associated with waste heat recovery and potential projects that use it, including the value of the heat, contract arrangements and sources of funding.

4.1 The value of waste heat

The potential value of waste heat depends on the following factors:

1. Temperature (i.e. grade) of the heat recovered and how suitable this might be for potential users.

2. Demand for the waste heat from parties who need it, known as heat offtakers. If there is higher demand, the potential value is usually higher. This can also vary seasonally.

3. Reliability of the waste heat supply. Without reliability in the short, medium and long terms, the offtaker will have to consider back-up alternatives to cover gaps in supply. This will negatively impact the potential value of the recovered heat.

4. The distance from the waste heat provider and the potential heat offtakers. Ideally, the offtaker would be as close as possible to the waste heat source to reduce infrastructure costs and heat losses in transit.

In general, a heat network connection is considered viable if the linear heat density (LHD) is more than 4,000 kWh/m/year, although this depends on other factors such as the marginal cost of the heat, the type of offtaker and desired return on investment. It is still worth recording heat opportunities even if LHD does not show an immediate opportunity.

There are several drivers influencing the recovery of waste heat, these include:

- Technological advancements mean methods of recovering or reusing waste heat are becoming cheaper, increasing the economic viability of projects. For example, heat pumps are becoming more efficient and cost effective. This allows previously unviable sources of low-grade heat to be utilised, with the upgraded heat being available for use in a wider range of applications.

- Advancements in technology (including the use of new operating fluids) are allowing heat pumps to produce higher output temperatures than have been previously available. This opens the door to a wider range of higher temperature applications where waste heat can be used.

- Traditional primary sources of heat are becoming more expensive, with rising/fluctuating energy prices, meaning waste heat recovery now carries a greater value, due to its lower and more stable price.

- Growing demand for district heating is backed by a strong regulatory framework in Scotland and emerging policy elsewhere in the UK. This is supporting the diversification of sources of heat that can be integrated into heat networks, therefore facilitating waste heat distribution.

- Implementation of carbon taxes or similar legislation could further increase the importance of energy efficiency and reuse of heat.

- Grid balancing is becoming increasingly important. Waste heat recovery could support this, either through reducing demand at peak times or offering back-up supply options.

4.2 Contractual agreements

Contractual agreements will govern the ownership of assets and equipment, set out roles and responsibilities for operation and maintenance, and will cover financial aspects like payment tariffs.

Commercial energy contracts can be complex and will be bespoke to the specific context in which waste heat is being recovered and used. The main themes for contractual agreements are introduced in the following sections.

4.3 Heat supply agreements

The relationship between a waste heat producer and a party receiving the heat, such as a district heat network (DHN) operator or an individual heat user would typically be governed by a Heat Supply Agreement (HSA).

The objectives set out by different parties in an HSA will vary upon their interests. These are typically linked to the physical assets they own, their role in the contractual order and their financial perspective.

There is no standardised template to facilitate contract development, and agreeing an HSA can take a significant amount of time. A key consideration for the most appropriate HSA is the management of risks associated with the supply of recovered heat. The governing principle is that risks should be allocated to the entity most adept at dealing with them. Nevertheless, this can be a complicated process which requires agreement from all involved. In allocating these risks, each party receives clarity on their rights and obligations. Key elements captured in a typical HSA are shown in Table 5.

| Aspect | Description |

|---|---|

| Annual heat supply availability | The amount of heat that is agreed to be supplied annually. |

| Peak heat supply availability | The peak heat that is agreed to be supplied at any given time. |

| Planned/unplanned interruptions | Agreed approach to outages and planned shutdowns. |

| Heat meter repair or replacement | Agreed approach and ownership of the heat meters and all their requirements. |

| Key performance indicators (KPIs) | Agreed service standards and the consequences of not meeting them. |

| Plant and ancillary plant ownership | Agreed management of plant and associated works. |

| Heat tariff derivation method | Agreed method of calculating the heat value and therefore price. Note, if the heat price can vary, how this would be reviewed and calculated within a defined time should be described. |

| Length of contract and exit clauses | The length of the agreement with a potential option for early termination of the agreement, and what circumstances could trigger this. |

| Complaint procedure | Agreed upon time and procedure to respond to a complaint from either party. |

4.4 Ownership and procurement

There are three main types of HSA depending on who owns the assets (i.e. heat recovery system, heat distribution network, heat pumps and energy centres):

1. Recovery and self-supply: self-supplying heat to meet or supplement heat demand within the generation site. This is the simplest mechanism, as one organisation typically owns all the waste heat recovery assets. An example is a whisky distillery recovering heat to reuse in its own operations.

2. Recovery then direct supply to third parties: often relates to a single organisation owning the heat recovery assets as well as the heat distribution network to supply the heat either to operations or buildings owned by a third party. An example is the recovery of heat from a manufacturing plant which is used by another industrial facility nearby.

3. Recovery then supplies to a network operator: heat recovered is sold into a heat network to be used by consumers. This is the most typical situation for recovered heat to enter a district heating network. An example is the recovered heat from supermarkets being sold to a district heat network operator.

The boundary of asset ownership can vary from system-to-system depending on factors including:

1. What heat recovery and distribution equipment will be installed and where it will be located.

2. Whether any leases or wayleaves are required to install the equipment.

3. Whether reusing waste heat will impact an organisation’s existing operation from a technical or commercial perspective.

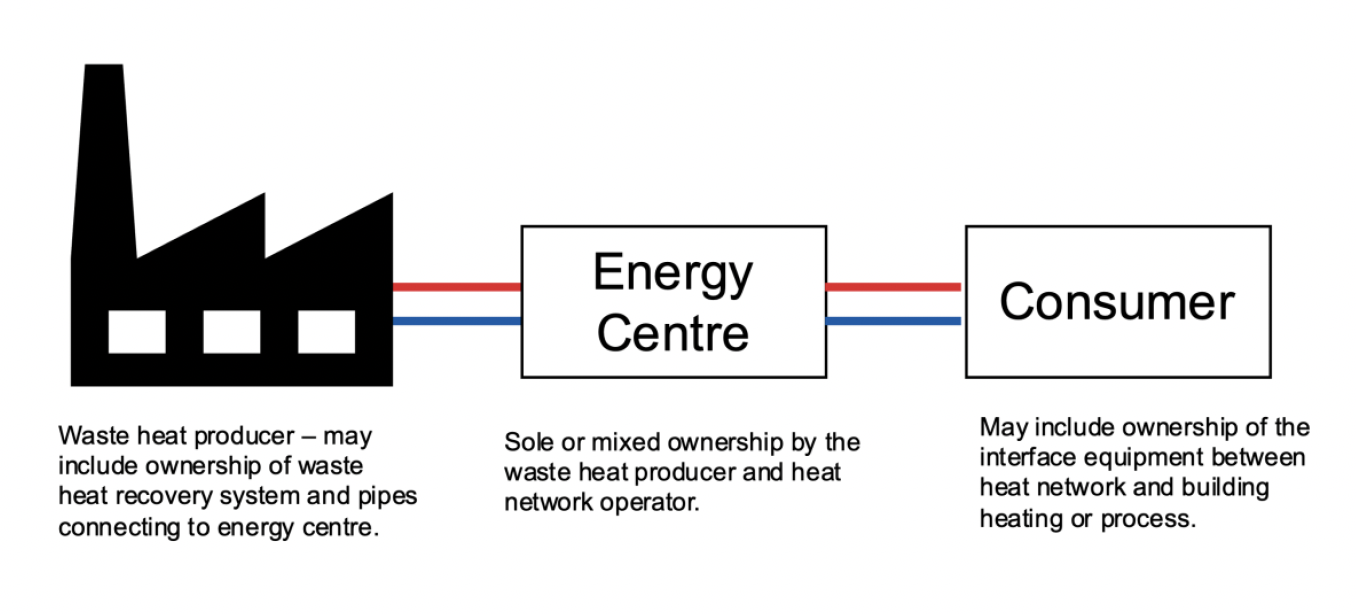

By way of an example, Figure 8 outlines the typical asset ownership boundaries between the waste heat producer, a district heat network operator, and the ultimate consumers of the heat.

If the waste heat recovery system impacts an industrial or commercial process or is located on a site owned by the offtaker, the offtaker may want a degree of control and there will be boundaries of responsibility set out in an HSA. Producers often prefer to sell this heat wholesale without the need to upgrade to a higher temperature.

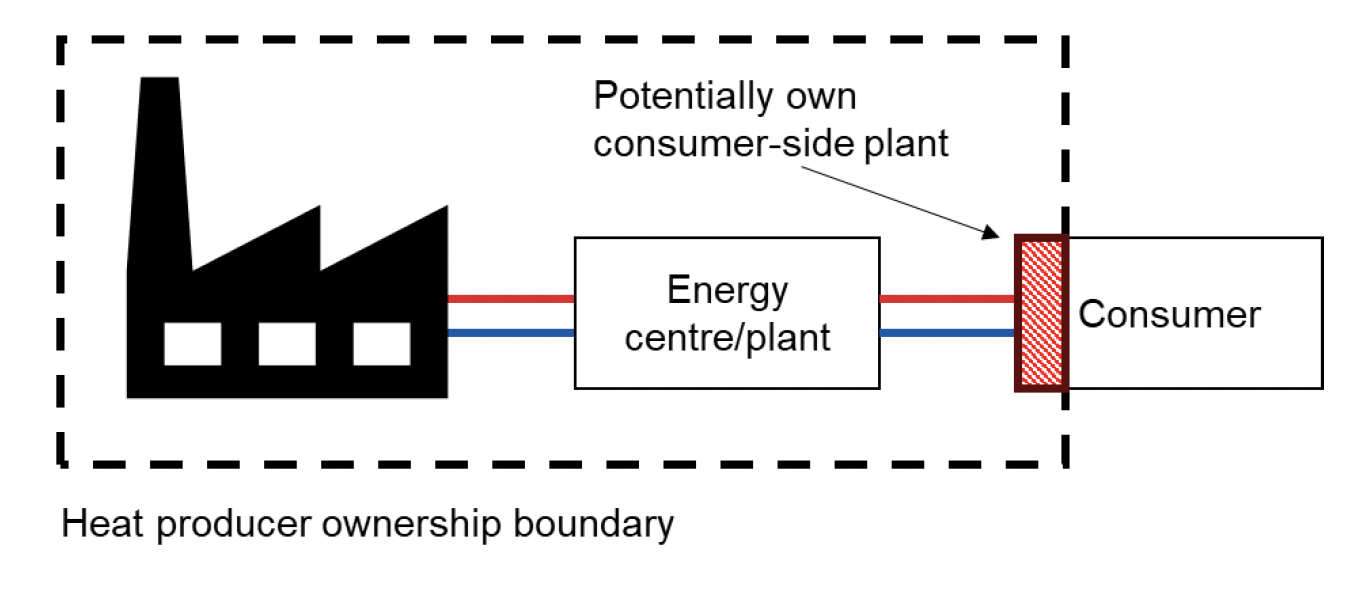

The diagrams and supporting text below briefly describe the advantages and disadvantages of various waste heat recovery asset ownership models.

Description: The waste heat producer owns all waste heat assets. An example of this is a manufacturing plant purchasing and then maintaining all heat recovery plant, including the distribution system.

This option is best suited to where there is a nearby offtaker.

Advantages:

- Contractual arrangements, if any, are simple.

- Potential risk reduction in areas such as maintenance, capital etc.

- Can make key decisions quickly (e.g. plant replacement).

- The waste heat producer has full control over the asset.

Disadvantages:

- Highest upfront capital cost for the heat producer compared to other options.

- Will have to source technical experts to design, select and maintain the plant.

- The producer bears all risk with this system.

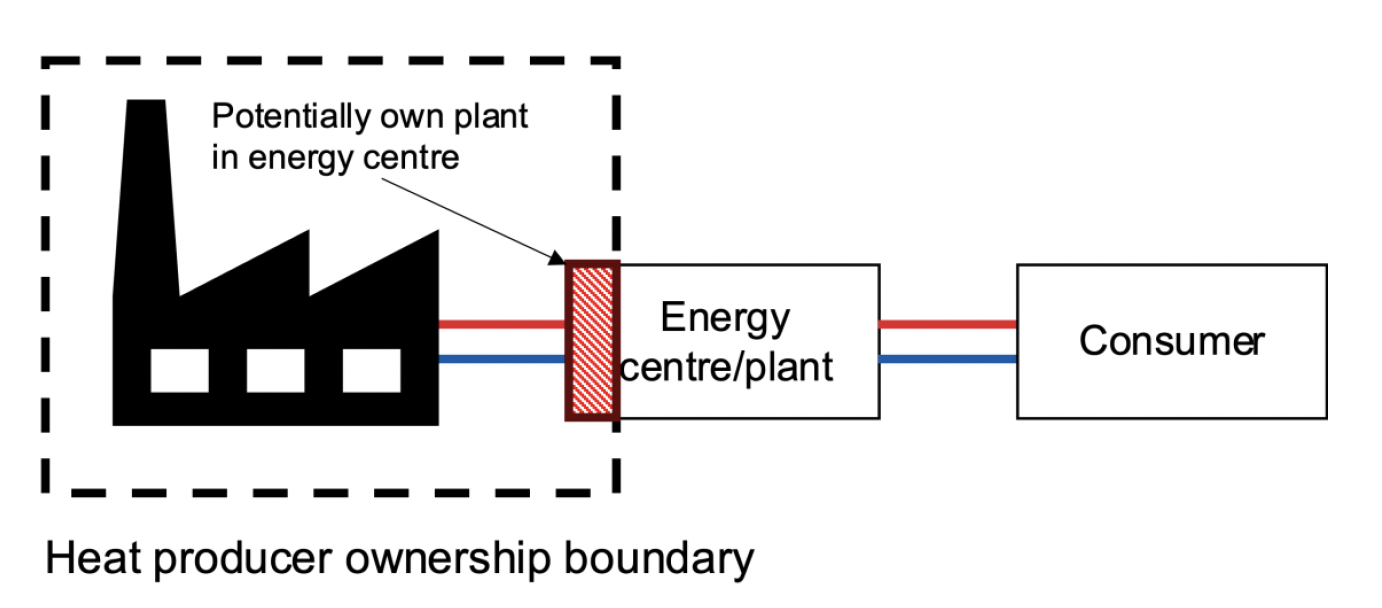

Description: The waste heat producer partially owns some or all of waste heat assets. An example of this could be an energy from waste plant that sends excess heat to a DHN, via an energy centre. Here they own the waste heat recovery system but not the main energy centre plant, or the distribution system.

This option may suit where there is a nearby district heat network.

Advantages:

- Potentially lower financial investment as multiple stakeholders are present.

- Risk and liabilities can be shared by multiple parties.

- Stakeholders can bring their own expertise and specialists which no one side could provide.

Disadvantages:

- Stakeholder management can be more challenging the more there are.

- Reduced profit and return on investment due to profit being shared between stakeholders.

- Decisions could be slower due to having to involve more stakeholders.

- Allocation of responsibilities can be complex.

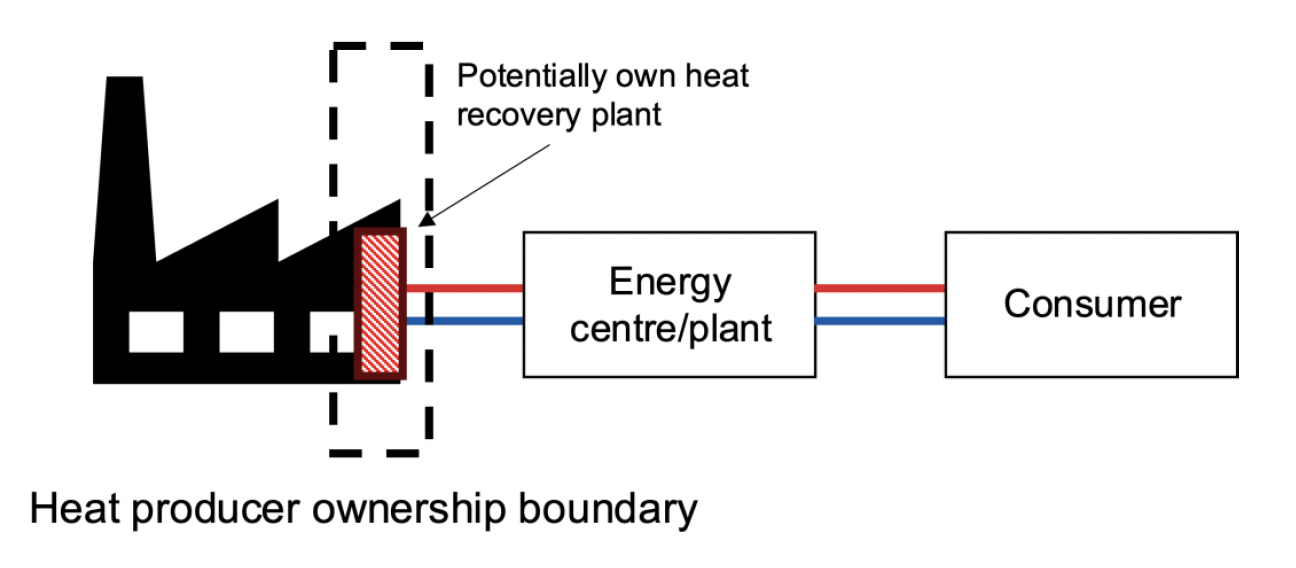

Description: The waste heat producer owns the minimal amount of plant infrastructure.

This may suit waste heat producers with minimal capital funds and/or nearby offtaker with a large heat demand.

Advantages:

- This option requires the minimal amount of capital investment for the waste heat producer.

- Waste heat producers can focus on their day-to-day internal operations.

- Reduced commercial risk in the event of plant failure.

Disadvantages:

- Risk levels are very dependent on the offtaker competence.

- Risk of having an external contractor having access to business operations.

4.5 Common heat procurement methods

There is a range of ways in which waste heat can be procured:

1. A direct bi-lateral negotiation between the heat producer and the offtaker - ownership option 1.

2. The heat “producer” going out to tender to secure a pricing and volume offtake to sell their waste heat – can be ownership option 1, 2 or 3.

3. A district heating network operator or industrial consumer going out to tender for a waste heat supply agreement (i.e. looking to identify parties who can provide them with waste heat).

4.6 Heat tariff development

A heat tariff is the amount of money charged for heat, either by a producer to an offtaker or consumer, or by a heat network operator to a consumer, usually measured in cost per unit of energy (e.g. p/kWh). Much like typical gas and electricity energy tariffs. There are many ways to derive them, including:

1. A cost-plus reasonable profit mechanism where the price of heat is based on the underlying costs for the producer plus a reasonable degree of profit. The underlying costs are indexed to appropriate mechanisms (e.g. Consumer Price Indexes).

2. A competitive discount to alternative sources of heat (e.g. 10% to 20% reduction in the price of heat vs. the cost of procuring the heat from alternative technologies). Future price indexation is tied to the evolution in the alternative price of heat (typically either forward natural gas or wholesale electricity prices).

3. Based on the regulated price of heat (where there is a Regulatory Price Control mechanism which determines the price of heat).

Heat tariffs should be designed to be competitive with existing energy tariffs to incentivise uptake, whilst allowing the various costs involved in recovering and distributing the waste heat to be recouped.

4.7 Financial mechanisms/ support

There are various funding routes for financial support to install and implement waste heat recovery technologies.

Support has in the past been available for waste heat recovery to support industrial decarbonisation, without the need to supply a district heat network. At time of writing, most of these schemes have closed their latest calls[17],[18]. However, it is likely further support may become available in the future.

4.7.1 Heat Network Support Unit (HNSU)

The HNSU offer guidance to support project identification and stakeholder engagement alongside stakeholder workshops and policy assessments[19]. In addition, funding can be granted for:

- Up to £50,000 for a detailed feasibility study.

- Up to £75,000 match funding for an Outline Business Case.

- Commercialisation costs, calculated on a case-by-case basis. Funding may be granted by the HNSU.

4.7.2 Scotland’s Heat Network Fund

The Scottish Government has made £300 million available to support the development of low or zero emission district heat networks3. Grant funding for this scheme must be drawn down by March 2026.

New low or Zero Direct Emissions district Heat (ZDEH) network projects are eligible, as well as the expansion of existing networks in a manner which continues to fulfil the ZDEH requirements. This includes supply from the recovery of energy / heat from industrial process, waste, or wastewater.

4.7.1 Capital allowances

Businesses can claim capital allowances and/or tax reductions to aid purchase of energy efficient, low, or zero-carbon technology from the UK government[20].

Contact

Email: heatnetworks@gov.scot

There is a problem

Thanks for your feedback